This occurs mostly with objects with a huge surface area in the first layers. The print bed crashes into the print head at the beginning of the print leading to a loud sound, as well as the print bed falls a bit down. Partial obstructions or blockages in your nozzle can prevent your filament from squeezing out appropriately, so cleaning your nozzle can additionally aid fix stringing in your 3D prints. As formerly pointed out, 3D model printing in Los Angeles you can cleanse your nozzle utilizing nozzle cleaning needles or doing a cold pull with cleaning filament.

This occurs mostly with objects with a huge surface area in the first layers. The print bed crashes into the print head at the beginning of the print leading to a loud sound, as well as the print bed falls a bit down. Partial obstructions or blockages in your nozzle can prevent your filament from squeezing out appropriately, so cleaning your nozzle can additionally aid fix stringing in your 3D prints. As formerly pointed out, 3D model printing in Los Angeles you can cleanse your nozzle utilizing nozzle cleaning needles or doing a cold pull with cleaning filament.

Certainly, some of these, like the equipments, call for certain devices, but a number of them are agnostic. Because it’s feasible to 3D print in a selection of products, the individual characteristics of a 3D printed part can be really various. Later in this guide, we will do a complete run-through of the products used in 3D printing. These 3 advantages inevitably result in much shorter preparation, which additionally connects to set you back financial savings. We have actually specified these three cost savers listed below and also just how 3D printing achieves them. Style features are effortlessly integrated within each cross-section as the part constructs, getting rid of the demand for tooling, labor extensive setting up, and also reducing time as well as component matter to lead to substantial expense financial savings.

Dispersed Production

The expertise of these methods is crucial for any person collaborating with 3D published parts, as it guarantees the successful integration of 3D printing technology in numerous sectors and fosters continued innovation in the area. Assistance structures are required for overhangs, bridges, and other intricate geometries that can not be printed by themselves because of gravitational forces. Nevertheless, assistance structures need to be eliminated after printing to attain the desired final look and performance of the component. There are a number of approaches for support elimination, each with its advantages as well as difficulties. For SLS published steel parts, warm treatment is a critical post-processing step to improve their mechanical residential properties and also alleviate inner stress and anxieties.

These are just a few of the special PLAs that different brand names provide. Makers are establishing brand-new PLAs all the time, so take a little time and check out what is available that may benefit you. Numerous makers give this number, so you understand what to expect. When you see a dimension such as ± 0.03 mm, that suggests the size of the filament differs by plus or minus 0.03 mm in width for the whole spool. Sugar is drawn from these resources, fermented, as well as turned into lactic acid.

On the other hand, it is harder to publish, and it calls for high warm from both the nozzle as well as the bed. Yes, PLA can be utilized for gears as well as it has been working efficiently for lots of customers that 3D print them. One example of 3D published equipments efficiently constructed of PLA is from a Geared Heart 3D print that contains relocating gears. Additionally, designing as well as printing your own components can save you a lot of time, since ordering substitutes for some devices can take a while.

material.Design balance. When a PLA filament takes in dampness, it swells up, increasing the risk of extruder jams. Moisture likewise triggers PLA to create prints with bubbles as well as gaps externally, for that reason destroying your prints .

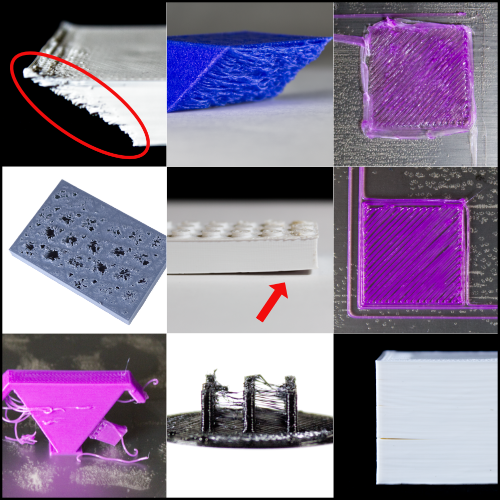

Both issues can be stayed clear of if the parameters are set properly. If you attempted both of those techniques yet the concern continues after that you most likely have an under-extrusion trouble. This trouble can be fixed by adhering to the repairing actions described in the following Over Extrusion & Under-Extrusion section of this short article. You’re seeing the print’s external covering different from the internal layers without any appearance of adhesion.

Attempt increasing the print temperature level (in 5 ° C increments) printing much faster needs increasing your print temperature level to thaw adequate plastic in time. Some slicers permit a strong diaphragm to be printed every many layers. This can be used to support succeeding infill layers (and as a spin-off, they can enhance the rigidness of the structure substantially). Infill is normally published in a routine pattern, like in a grid, or boxes and even honeycomb structures.

Attempt increasing the print temperature level (in 5 ° C increments) printing much faster needs increasing your print temperature level to thaw adequate plastic in time. Some slicers permit a strong diaphragm to be printed every many layers. This can be used to support succeeding infill layers (and as a spin-off, they can enhance the rigidness of the structure substantially). Infill is normally published in a routine pattern, like in a grid, or boxes and even honeycomb structures.

The electric motor might have overheated, enable to cool down and also see if it takes place again. Some filaments draw in and also absorb moisture from the air at extremely high prices. When attempting to print such filament, the wetness will certainly develop into vapor and also give little popping sounds. Many typically as a result of build up on the nozzle of a dripping HotEnd, but can be worse with particular products. It not just looks bad, especially if it lands on one of the outer surfaces, it can ruin your print when your HotEnd strikes it on the next pass. We have actually had several instances where a decline like this harmed some of our printers.

Chasing After The Evasive Secure 3d Printer Resin

Frequently caused by retraction settings, extra filament balls out as well as onto the print. A short-term problem with the filament not unspooling cleanly may have obstructed the movement of the extruder triggering your 3D model printing in Los Angeles printer changing layers. Attempting to print too quick will create the motors to avoid, resulting in 3D printing innovation in LA printing layer changing. You can be attempting to publish using a layer elevation that is too expensive for your nozzle.